New technologies—including machine learning, mobile apps and advanced analytics—help manufacturers keep tabs on fast-paced factory-floor operations

Original Article via :: Manufacturing Engineering

Article by Patrick Waurzyniak

Manufacturing operations depend on getting the right information at precisely the right moment, ensuring that products get built on time, to quality specs. With the latest enterprise resource management (ERP) software, this critical data flow is often coming via the cloud, as more manufacturers become comfortable with it as a repository for key manufacturing information.

With ERP software delivered via the cloud, Big Data is also more easily leveraged for Industrial Internet of Things (IIoT) applications. In this application, advanced analytics do the data crunching required for processing the flow of data, including operational metrics and inventory information.

Along with offering more mobile apps that funnel factory data directly to users’ fingertips, many ERP software developers are also testing newer technologies like artificial intelligence, augmented reality/virtual reality (AR/VR) capabilities, and machine learning and advanced analytics that can handle the Big Data inherent with many IIoT/IoT manufacturing data scenarios.

IIoT and Manufacturing’s Big Data

With advances in Smart Manufacturing/Industry 4.0, the potential for growth in the IoT/IIoT is immense, noted Jerry Foster, cofounder and chief technical officer of ERP software supplier Plex Systems Inc. (Troy, MI), developer of the Plex Manufacturing Cloud ERP. “The IoT and the IIoT [concept] is just huge,” Foster said, noting that while many managers seem to think they’re falling behind, “this is stuff that they’ve been doing for years—it’s just a matter of scale. The enabler there is just the cloud and connectivity.”

Data collection is something many manufacturers are already doing, so they’re ahead of the game, Foster noted. “Big Data for you is just Bigger Data,” he said. “It’s more data than you have now. The problem with this is data deluge. It was a major concern, but it only takes machine learning and algorithms to handle it.”

Plex currently offers machine learning and advanced analytics through third-party applications. However, the company is working on its own applications for this process that Foster said will be available later this year. “What we do is partner with a machine learning service and utilize that to analyze the data. We’d take the ERP data that our customers have and put that in the Microsoft Azure cloud. You want actionable machine learning, and this is one of the things that we’re on the cusp of right now,” he said.

Many other ERP developers recognize the importance of Big Data in the IIoT age, and they are moving to incorporate advanced analytics and AI into their toolkits. “Big Data is already having an impact on the ERP software market, and many manufacturers understand this,” said Terri Hiskey, vice president, manufacturing product marketing, Epicor Software Corp. (Austin, TX). “The insights that can be revealed through the collection of all sorts of data—from the length of time it takes to process orders and respond to customer requests, to tracking materials and costs, tracking inventory, understanding customer patterns and behavior, and much more can be tracked through various algorithms and analytics.

“As manufacturers move into the IIoT, the amount of data increases because now companies can track machine performance out in the field,” she continued. “Depending on performance outcomes, those machines might be set up to course-correct themselves through artificial intelligence. In fact, a term that I hear being used more and more is ‘data fatigue’; that the vast amount of data being collected is often left untouched because there aren’t enough resources or knowledge to make that data actionable. The advantages that companies will get out of leveraging Big Data is the insight into overall ERP processes and the recommended actions to take due to those insights.”

Managing the Workflow

For discrete manufacturers, ERP software helps streamline the process, ensuring workflow is optimized to meet production goals. “Just by creating the workflow in ERP, the business captures the experience, expertise and best practices for the varying workflows,” Hiskey said. “The workflow can be automated in ERP, resulting in less human error and a faster process. Guesswork can be reduced with greater visibility and insights into the business. ERP workflow can cross cross-functional boundaries and allow for easier communications up and down and across the organization and functional areas.”

Businesses can also track the total execution time for any given workflow, she added. “ERP workflows can also help track costs and time related to the completion of a production job, such as whether or not the time falls within an agreed upon timeline; whether all materials were consumed and charged correctly; are there any orders outstanding waiting for the completion of this job; do labor or material costs need to be updated for future production; and are there any corrections to costs before completing the job?” This can help accounting teams close their books, Hiskey said, with information on invoices that need to be completed and posted to accounts receivable; suppliers that need to be paid and costs captured; and making sure that depreciation and accruals are calculated. “All of these steps can be managed through an ERP workflow,” she added.

Users of Epicor’s latest ERP get a personalized, active home page that “provides dashboard views of role-based analytics with quick access to role-based functionality, made possible through Epicor Data Discovery, which supports rich, on-demand data exploration to surface real-time operational and business performance insights to guide decision-making,” Hiskey said. “This results in users being able to access critical insights at a glance for better, faster analysis and execution.”

New customer relationship management (CRM) functionality in Epicor ERP empowers sales and service personnel in the field with the added convenience of mobile access, she added. Epicor Field Service Automation (FSA) features integrated mapping to support optimized scheduling and dispatch and robust workflows to automate processes for asset management, contract, warranty and service level agreements (SLAs), and management of service inventory. Hiskey said the Epicor FSA is available in a cloud or on-premises delivery model and can be used with smartphones, tablets and laptops for both online and off-line communications with the back office for enhanced productivity and efficiency across all service workforce facets, for improved response, reduced costs and improved customer satisfaction.

“Most ERP systems today are very mature and are designed around industrial best practices,” noted Jim Errington, executive vice president, sales and service for ERP software developer CrescentOne Inc. (El Segundo, CA). “So if instead of customizing the software to fit what the customer has always done, the customer has to change and actually review what the software is really offering.

“A lot of ERP systems are now using software such as SharePoint to assist in documenting and defining the processes,” he added. “So when using the solution, users don’t need to access the ERP solution directly but can be steered by the process to use the necessary screens to complete the process,” he said.

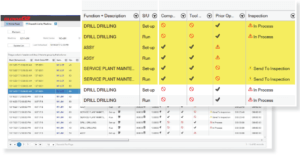

The latest GLOVIA G2 ERP software includes a new call center capability and CRM functionality in new modules that allow monitoring activity by cell or machine in real time on the factory floor (seen above).The CrescentOne ERP includes a new Call Center capability, he added, as well as a CRM solution suitable for discrete manufacturing customers. “In the next release there will be a couple of new modules. The first, Shop Floor Dispatch, allows manufacturing to monitor activity by cell or machine on the factory floor in real-time, giving them the ability to react to problems,” Errington said. “The second, Contract Billing, allows customers to create billing contracts to cover things such as machine rentals and service contracts without the need to start with a sales order or sales contract.”

The latest GLOVIA G2 ERP software includes a new call center capability and CRM functionality in new modules that allow monitoring activity by cell or machine in real time on the factory floor (seen above).The CrescentOne ERP includes a new Call Center capability, he added, as well as a CRM solution suitable for discrete manufacturing customers. “In the next release there will be a couple of new modules. The first, Shop Floor Dispatch, allows manufacturing to monitor activity by cell or machine on the factory floor in real-time, giving them the ability to react to problems,” Errington said. “The second, Contract Billing, allows customers to create billing contracts to cover things such as machine rentals and service contracts without the need to start with a sales order or sales contract.”

Banking on the Cloud

Moving to the cloud is an important consideration for many manufacturers today. With the latest M1 ERP solutions from ECi Software Solutions Inc. (Fort Worth, TX), manufacturers can leverage the cloud in multiple ways, noted David Christiansen, ECi Solutions vice president of sales.

Moving to the cloud to take the stress and costs of managing hardware from the customer is key, he said. “The main trend is moving towards the cloud and especially mobility. … ERP packages provide the data to make informed business decisions on the floor. This could be utilizing machines on the floor or improving material handling,” Christiansen said.

“The cloud is important today due to the increase in ransomware attacks and the need to have a solid redundancy plan,” added Christiansen. “We will still have manufacturers with on-premise [data storage] due to location and limited Internet access.”

Leaders of growing manufacturers know that innovation is not only critical but imperative, said Epicor’s Hiskey. “Faced with rapid change, they are choosing to invest in business initiatives that accelerate innovation as a competitive advantage, like a range of cloud-based business applications. The cloud has rapidly established itself as the preferred and default deployment environment for companies of all sizes, particularly small to mid-size,” she added.

Customers typically select the cloud for a host of economic reasons. It is less-capital intensive than on-premises deployment and offers better and more immediate scalability; ease of upgrades; the ability to cut direct and indirect costs from infrastructure; and reduced deployment times and corresponding ROI, noted Hiskey. “However, the reasons aren’t all about technology, nor economics,” she said. “Selecting cloud means retiring the status-quo approach to business management applications that could not keep pace with current business needs. Moving to the cloud frees companies from the need to procure, install, maintain and manage their own IT systems, while also gaining the opportunity to digitally transform business processes to achieve far greater results.”

Many manufacturers are still working with on-premises solutions for a number of reasons, Hiskey said, including security concerns, aversion to shaking up the status quo, lack of expertise or knowledge of how to start process improvements, and fear of the cost or downtime during a transition period. “There could be any number of reasons why manufacturers might decide to stay on-premises.” Epicor offers the same solution as either cloud or on-premises, so companies can choose the model that works best for their businesses, she added.

Whether the system is in the cloud or on premise, manufacturers still have to implement the solution, Errington noted. “With cloud, this is difficult for manufacturing companies as they often want to change things in the standard software, so unless it is a single-tenant solution then there are difficulties,” he said.

In addition, manufacturing execution systems (MES) and advanced planning and scheduling require a lot of bandwidth, and connections to the cloud solution can be difficult, Errington said. “Just about all of our customers still want an on-premise solution so that they have control and the ability to modify it when required,” he added.

Visualizing Shop Processes

New wearable technologies such as Google Glass and others that employ augmented reality (AR) are being tested and implemented on the shop, noted Foster. “This is one more interesting thing,” he said. “The hype has cooled a bit, but we’re working on some proof of concept.”

Plex customer Fisher Dynamics (St. Clair Shores, MI), an automotive seating supplier, has tested a system using Google Glass with a barcode system featuring iBeacon and Plex ERP for improving its inventory control and meeting traceability requirements.

Aside from Google Glass, there are other options, including the Realwear HMT1 or the Vuzix Blade AR glasses recently announced by Vuzix Corp. (Rochester, NY) at the CES 2018 show, Foster noted. “The cool thing about them is they utilize voice activated commands,” he said. “At the CES, voice was everywhere.”

Using this type of technology, combined with Plex ERP’s ability to focus users on one single repository of information, is a winning combination for discrete manufacturers, he said. “You get one version of the truth,” Foster added. “You hear a lot about the connected enterprise; ERP connects the whole enterprise, it’s cohesive and it provides one source of the truth.

“When we take Plex into a new customer, we’re often replacing several applications,” Foster continued. “You don’t have a situation where accounting has one software, and inventory has another, and you have arguments like ‘my software says this.’”

Mobile access also is key, offering managers immediacy in getting key performance indicators right on the shop floor. “Our software, since it’s HTML, can run on smartphones or tablets, but obviously the bigger the screen the better. We do have an app, SmartPlex, that runs on Android and iOS devices.” Plex is currently overhauling SmartPlex, he said, with a new version of the app due in the second half of this year.

This article was first published in the December 2016 edition of Manufacturing Engineering magazine. Read “Cloud Connectivity, Advanced Analytics Drive ERP Software.”

Advanced Manufacturing Media – SME

U.S. Office | One SME Drive, Dearborn, MI 48128 | Customer Care: 800.733.4763 | 313.425.3000 | sme.org

Canadian Office | 7100 Woodbine Avenue, Suite 312, Markham, ON, L3R 5J2 | 888.322.7333

Tooling U-SME | 3615 Superior Avenue East, Building 44, 5th Floor, Cleveland, OH 44114 | 866.706.8665 | toolingu.com

© Copyright 2016 SME · All Rights Reserved

Contact CrescentOne for more information on how GLOVIA G2’s ERP Solution can keep tabs on fast-paced factory-floor operations, while giving you a customizable solution to fit your business needs.